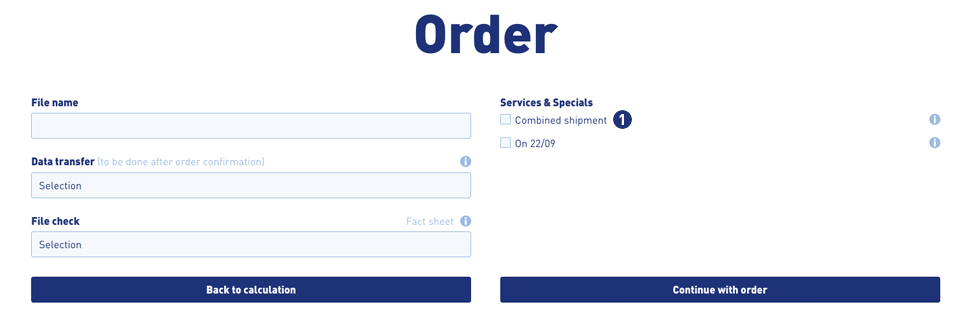

If desired, the print data can now be selected and uploaded on the calculation page. In addition, there is the option of viewing the uploaded print data via a preview function after the upload process.

On the calculation page, there is a selection list with the name “Print data”. Here, you can choose between the following options.

- Transfer print data later

The upload takes place as usual after order completion including print data preview. - Upload print data now

The upload takes place directly on the calculation page including print data preview.

After selecting one of the options above, a layer for the login or guest login is displayed.

Log in there with your user data. Then select the desired print file. Click on the button “Choose print data”. The selected file will be displayed in the window above. Confirm your selection with the button “Upload print files”. The upload process is displayed via a status bar.

Afterward, you have the opportunity to preview and check the previously uploaded print data. Click on the button “Show uploaded print data”.

If the data are correct, confirm your selection via the button “Use uploaded print data”. Otherwise, you can delete the print data. Click on the button “Delete uploaded print data”. You will be redirected to the selection window for the print data upload.

Afterward, you get back to the calculation page. In the selection list “Print data” the selected upload option as well as a preview link (View) are displayed.

Note

Due to security issues, uploading archive files (e.g., zip, rar, tar, gz, etc.) is no longer possible.

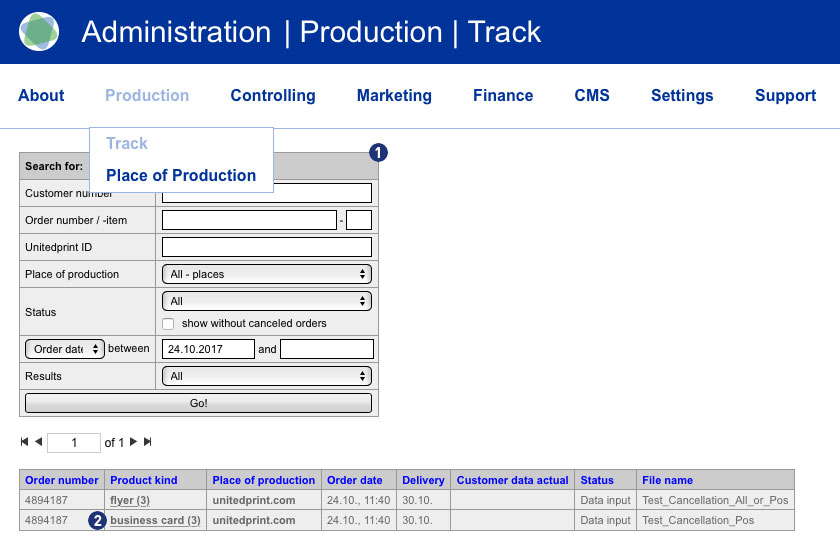

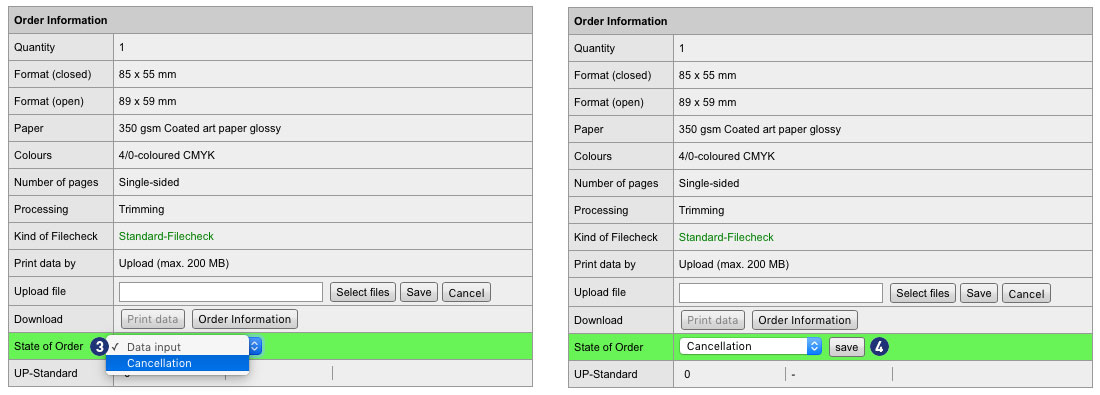

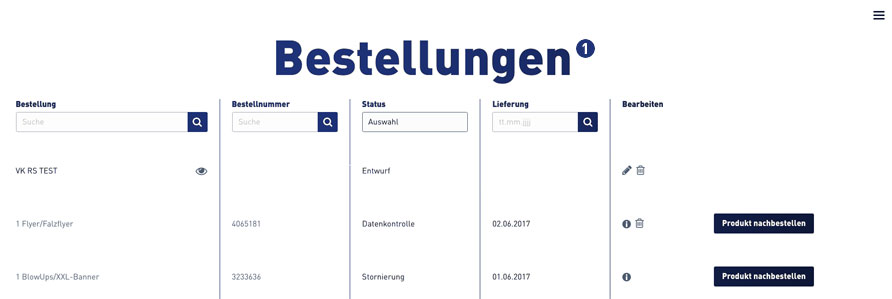

Select print job, click on “Upload print data”

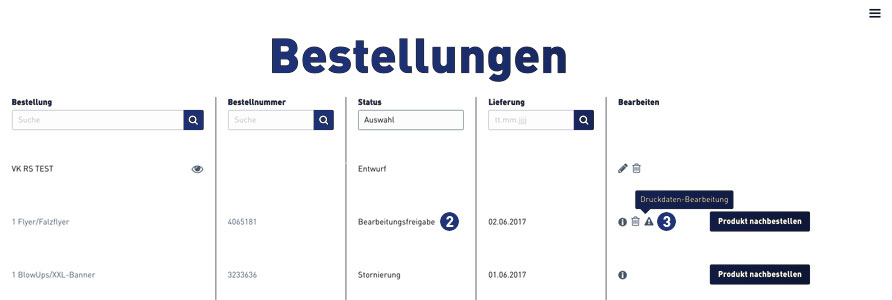

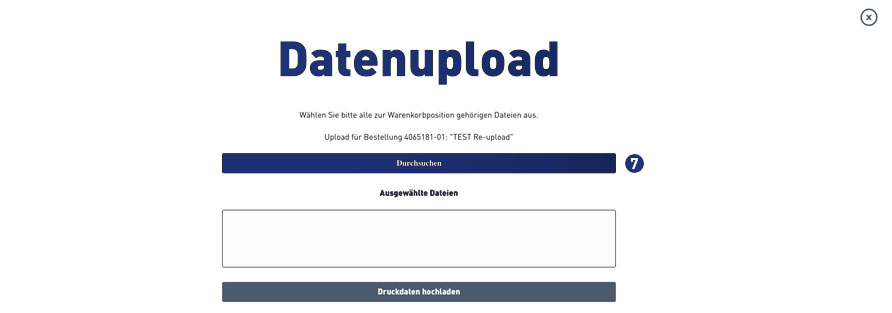

Select print job, click on “Upload print data” Select print data – click “Browse”

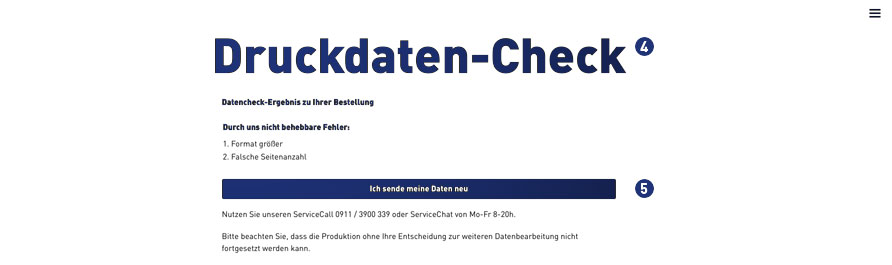

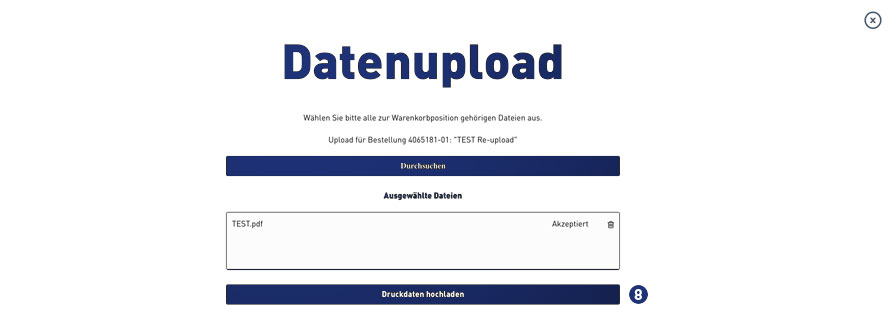

Select print data – click “Browse” Analysis of the print data – accepted – click on “Upload print data”

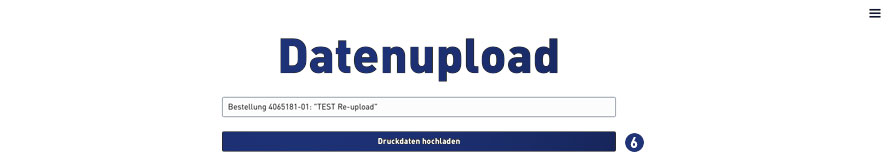

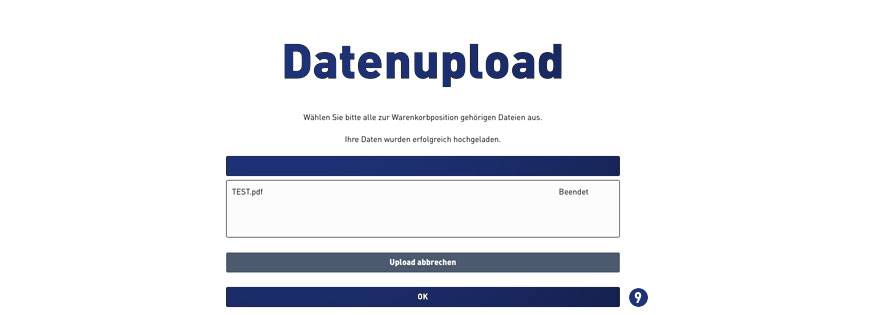

Analysis of the print data – accepted – click on “Upload print data” Status file upload – when “finished” continue with click on button “OK”

Status file upload – when “finished” continue with click on button “OK”